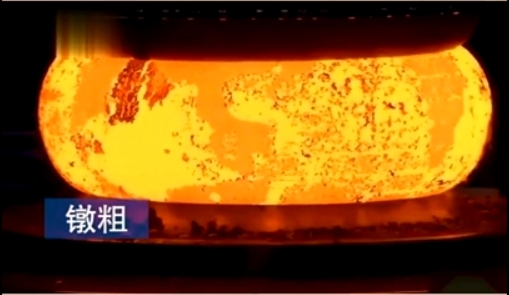

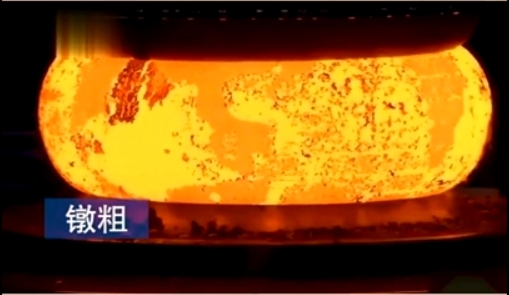

The free forging hydraulic press is mainly used to perform all processes of free forging, such as upsetting, elongation, punching, hole enlargement, bending, displacement, and shearing of metal plastic materials. It is primarily used for producing forged products composed of shafts, bars, plates, discs, rings, circles, and squares, and is widely applied in the forging of carbon steel, alloy steel, stainless steel, high-alloy steel, and other non-ferrous metals. It offers significant advantages in terms of internal and external quality of forged materials, yield rate, dimensional accuracy, automation level, production efficiency, as well as environmental protection and operator safety.

Huzhou Machine Tool's free forging hydraulic press features human-machine interface input display, PLC control, and multifunctional and multi-directional real-time monitoring capabilities. The equipment control system offers manual/linkage working modes, allowing for the linkage of the press and operating machine in a 1+1 configuration. The hydraulic system adopts a modular valve integrated system, with the main cylinder pressure relief and rapid descent controlled by proportional valves for flexible adjustment and reduced impact and vibration. The equipment comes with speed grading selection function for energy-saving usage and improved efficiency. The main oil pump can be driven by a servo motor, providing advantages such as energy-saving, noise reduction, and reduced heat generation from oil overflow.

Technical Parameters:

| No. | Content | Unit | Specifications |

| 1 | Nominal Force | KN | 8000 | 12500 | 16000 | 20000 | 25000 | 31500 | 40000 | 50000 | 60000 |

| 2 | Pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| 3 | Main Cylinder Diameter | mm | φ630 | φ800 | Φ630/2-φ450 | φ710/2-φ500 | φ800/2-φ560 | Φ900/2-φ630 | Φ900/2-φ800 | 3-φ920 | Φ980/2-φ900 |

| 4 | Space Distance | mm | 2200 | 2600 | 2800 | 3100 | 3200 | 3800 | 4000 | 4500 | 5200 |

| 5 | Slider Stroke | mm | 1000 | 1200 | 1400 | 1500 | 1600 | 1800 | 2000 | 2200 | 2500 |

| 6 | Spacing Between Pillars | Left-Right | mm | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 | 3000 | 3300 | 3600 |

| Front-Back | mm | 800 | 1000 | 1100 | 1200 | 1400 | 1600 | 2000 | 2200 | 2200 |

| 7 | Slider Speed | Return | mm/s | 300 | 300 | 300 | 250 | 250 | 250 | 200 | 200 | 200 |

| 工作 Work | mm/s | 50 | 50 | 50 | 50 | 50 | 40 | 40 | 40 | 40 |

| 下行 Descent | mm/s | 300 | 300 | 300 | 250 | 250 | 250 | 200 | 200 | 200 |

| 8 | Movable Worktable Size | Left-Right | mm | 1500 | 1600 | 1800 | 2000 | 2200 | 2400 | 2500 | 2800 | 3000 |

| Front-Back | mm | 3000 | 3000 | 3600 | 4500 | 5000 | 6000 | 6000 | 6000 | 7000 |

| 9 | Movable Worktable Stroke (front to back) | mm | 1000 | 1000 | 1500 | 1800 | 1800 | 2000 | 2000 | 2000 | 2500 |

| 10 | Movable Worktable Speed | mm/s | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| 11 | Maximum Allowable Eccentricity | mm | 100 | 100 | 150 | 200 | 200 | 200 | 250 | 250 | 250 |

| 12 | Maximum Forgable Steel Ingot (Upseeting/Elongation) | T | 2.5/5 | 5/8 | 8/15 | 12/20 | 20/40 | 25/45 | 36/65 | 40/80 | 60/130 |

| 13 | Installed Power | kW | 440 | 660 | 880 | 1100 | 1320 | 1320 | 1650 | 2100 | 2500 |

| Customization is available according to user or process requirements. |